- Home

- About Us

- Products

- Support

- Awards & Achievements

- Enquiry

- Contact Us

Product

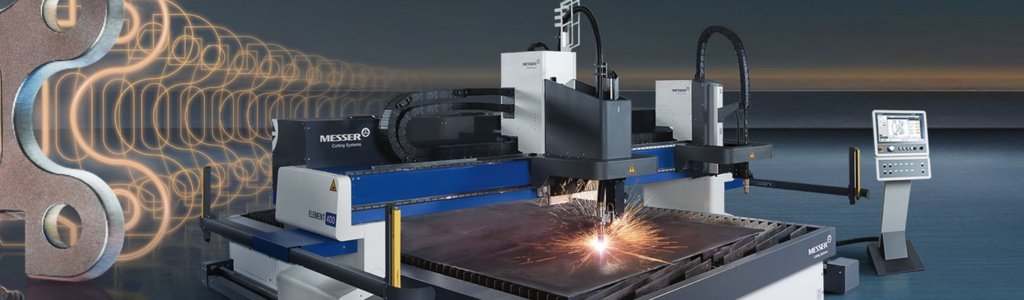

The ELEMENT 400 is a remarkable cutting machine designed by Messer Cutting Systems. Let’s delve into its features:

Productivity Redefined:

The demands on your production are continually increasing. As a solution provider, we therefore focus entirely on your needs. Continually providing increased efficiency, reliability and quality: we know what today’s metal processing industry requires from you – with our new, flexible ELEMENT platform we are already setting the course for a successful future today. Apart from the high level of productivity and precision you have come to expect from us, this solution offers customised configuration options and updates, enabling you to respond to future requirements. This gives you a real competitive edge – helping you to stay ahead in the long run.

The new, easy-to-operate Global Connect CNC control equipped with 18.5” touchscreen helps to save paper and provides a clear overview of all production data in digital form.

Selected premium components and smooth, vibration-free tool path movements thanks to helical rack and pinion drive systems

Compliance with all applicable standards and specifications, e.g. through the use of a moving light barrier

Floor mounted rails for clearing and unloading of parts leads to time savings

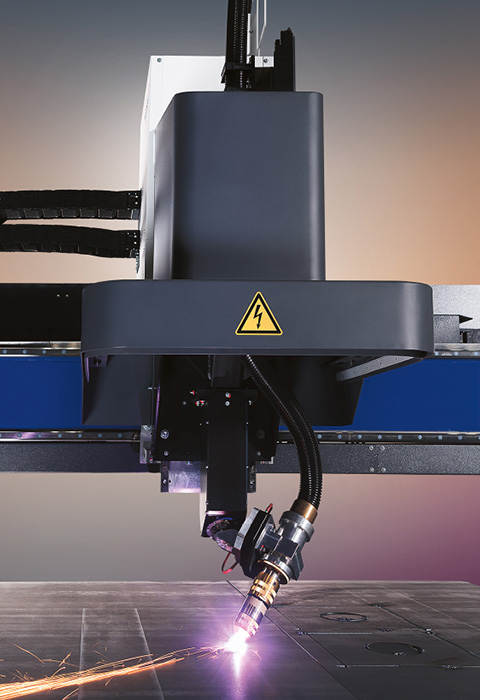

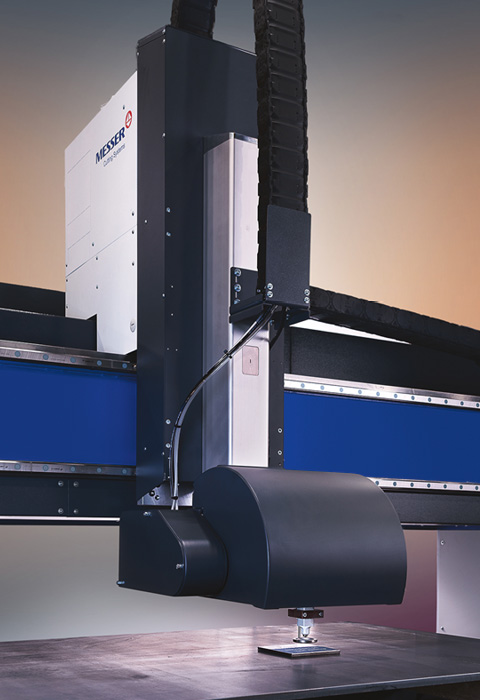

From complex contours, holes or bevels for welding seam preparation: the new Delta has been developed specifically for use with the ELEMENT platform and provides a very high degree of flexibility. It enables precise bevel cuts within an angular range from +45° to -45°. The process is controlled by Global Connect, allowing you to perform all preparatory work in next to no time. High-acceleration ±540° rotation enables you to use your machine at maximum efficiency. For a perfect result, the torch height is controlled automatically and precisely throughout the entire cutting process based on the arc voltage. Throughout the development of the torch, special attention was paid to function and low wear of materials.

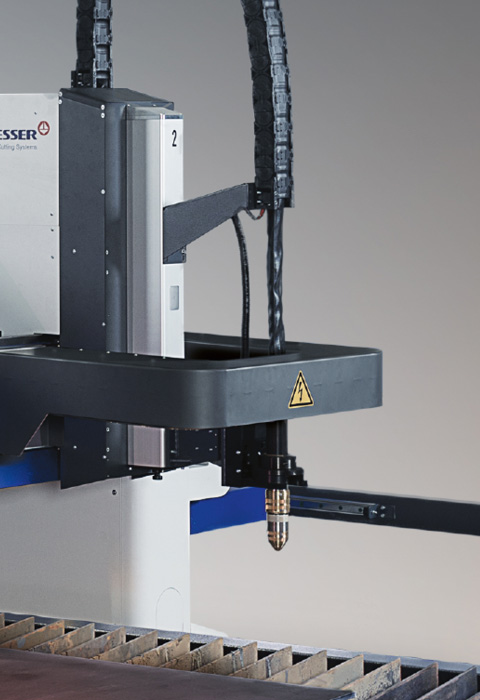

Our compact 5-axis bevel cutting unit with collision protection is the entry-level solution for occasional bevel cutting.

With ±45° cuts and quasi infinite rotation, the Bevel-R does not only allow cuts at a right angle, but also bevel cuts from V, X or Y on simple contours for subsequent welding processes.

EGP Sales Corporation